Simplifying Manufacturing Performance with In-Mold Decorations

Simplifying Manufacturing Performance with In-Mold Decorations

Blog Article

In-Mold Decorations Demystified: Opening the Tricks Behind This Advanced Manufacturing Process

In today's busy production landscape, in-mold designs have actually become a sophisticated strategy that remains to intrigue sector specialists. This advanced manufacturing process holds the pledge of revolutionizing the way we view and use attractive components in numerous items. As we explore the details of in-mold decorations, a globe of innovative possibilities unravels, offering a glimpse into a realm where style satisfies performance in a seamless combination. In-Mold Decorations. Remain tuned as we explore the underlying principles and unveil the enigmatic appeal of in-mold decors, shedding light on the secrets that push this process to the forefront of modern manufacturing approaches.

The Development of In-Mold Decorations

The evolution of in-mold decors has actually been marked by considerable developments in modern technology and layout technology. In-mold decorations were restricted in their complexity and shade choices. With the introduction of brand-new manufacturing strategies and materials, the opportunities have increased tremendously.

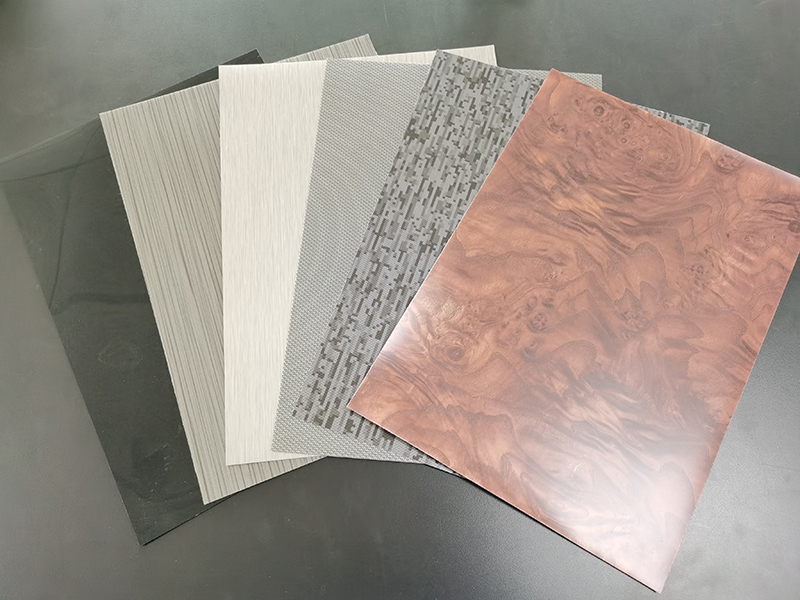

One key improvement has been the advancement of high-resolution printing processes that enable elaborate designs with dynamic colors to be transferred onto items during the molding procedure. This has made it possible for makers to attain photorealistic pictures and thorough graphics that were previously unattainable.

In addition, the integration of robotics and automation in the in-mold design process has boosted efficiency and consistency in using decorations to products. This not just reduces manufacturing time but also improves the total quality of the finished items.

Understanding the In-Mold Refine

Marked by considerable advancements in innovation and style technology, the evolution of in-mold designs has actually led the way for a deeper understanding of the complex procedure entailed in creating these decorative aspects. The in-mold process is an advanced production strategy where attractive components are incorporated straight into the end product throughout the molding procedure. This approach entails placing a pre-designed decoration, such as a graphic or label, into the mold cavity before injecting the material. As the material moves right into the mold and mildew, it bonds with the decor, causing a smooth integration of the design into the item.

Recognizing the in-mold procedure needs exact control over various parameters, consisting of pressure, timing, and temperature level, to make sure the decoration sticks effectively to the item. Furthermore, selecting the appropriate materials is crucial to attaining top notch results. By understanding the ins and outs of the in-mold process, suppliers can create aesthetically striking products with sturdy, lasting decors that improve both the aesthetics and performance of the end product.

Advantages of In-Mold Decorations

Advancing product aesthetics and toughness, in-mold decorations use a structured method to incorporating decorative aspects throughout the production process. Among the vital benefits of in-mold decors is the seamless assimilation of shades, structures, and graphics straight into the item during the molding process. In-Mold Decorations. This gets rid of the demand for post-production decoration methods, such as paint or printing, which can be time-consuming and costly

Moreover, in-mold decorations are highly resilient as the graphics are enveloped within the item, making them immune to put on, scrapes, and fading. This results in items that keep their aesthetic appeal and branding for a longer period, even in severe atmospheres.

In enhancement to improving aesthetics and toughness, in-mold decorations also offer increased design flexibility. Producers can quickly integrate elaborate styles, appearances, and branding components that would certainly be tough or difficult to accomplish with standard decoration methods.

Applications Across Industries

Across numerous markets, in-mold decors have actually found flexible applications that boost both the visual appeal and toughness of items. In addition, the appliance market uses in-mold decors to develop durable and stylish control panels and fascia for products like refrigerators and ovens. Generally, in-mold decors supply a cost-effective and efficient method to improve the aesthetics and resilience of items throughout a large array of sectors.

Future Fads in In-Mold Technology

The evolution of in-mold decors is poised to proceed forming the landscape of product layout and production as Future Trends in In-Mold Technology guarantee cutting-edge services to better enhance aesthetic aesthetics and item durability. Additionally, innovations in digital printing methods are making it possible for producers to attain greater personalization and information in in-mold decorations, opening up new opportunities for creative product layouts. Another significant pattern is the assimilation of wise innovations, such have a peek at this site as NFC tags or LED illumination, directly right into in-mold decors, including interactive and practical aspects to items.

Final Thought

In-mold designs have revolutionized the production process by perfectly incorporating layout elements into items. Recognizing the intricacies of this process is critical for industries seeking to boost their items with sturdy and visually attractive decors. With its numerous benefits and versatile applications across different markets, in-mold modern technology is positioned to proceed evolving and shaping the future of manufacturing. Remain notified and stay ahead in this innovative area.

By mastering the complexities of the in-mold process, producers can produce visually striking items with long lasting, resilient designs that enhance both the aesthetic appeals and performance of the final product.

Progressing item aesthetic appeals and toughness, in-mold decorations supply a streamlined strategy to incorporating ornamental aspects during the production procedure. One of the essential benefits of in-mold decors is the seamless integration of check these guys out structures, graphics, and shades directly into the item during the molding procedure.The development of in-mold decorations is positioned to continue forming the landscape of product layout and manufacturing as Future Trends in In-Mold Modern technology guarantee innovative remedies to even more boost visual aesthetics and item resilience.In-mold decors have changed the production look these up process by flawlessly integrating layout elements right into items.

Report this page